Wellsmart Energy has highly qualified team of professionals who offers innovative engineering, fabrication, and construction solutions with a fully integrated process from conception to operation. Our engineering and fabrication services are complemented by full site services for installing and commissioning a wide variety of energy processing solutions. Not only do we offer expertise that encompasses the full scope of a project, we also cater to multidisciplinary engineering fabricators

SERVICES

Engineering

Through our Technical Partnership with JX we have assembled a talented team of engineers, technologists, designers, and support staff to serve our customers’ needs. Our multidisciplinary engineering group is capable of meeting the diverse requirements of oil and gas production and process equipment. The group consists of process engineering, mechanical engineering, piping engineering, structural engineering, electrical engineering, and instrumentation and automation.

Process Engineering

Our process engineers outline the full scope of each plant project and know how best to increase efficiencies, improve safety, and maximize product recovery. The process engineering department has a team-oriented environment, with group members reporting to project team leaders and department group managers. We interface with clients and vendors to define project scope, resolve technical issues, and assist with preparation of procurement documents. We also work with other internal engineering disciplines to ensure a coordinated design and complete engineering deliverables.

Our process engineers:

- Generate block flow diagrams and process flow diagrams as well as piping and instrumentation diagrams

- Prepare the process design basis, utility consumption reports, equipment lists, line lists, tie-in lists, and overall process system construction specifications

- Complete relief valves and flare system analysis and final reporting, including the sizing of the relief valve inlet and outlet line sizing

- Incorporate conceptual designs and provide process development reports, as well as hazard and risk-reduction reviews on all projects (e.g., HAZOP, HAZID, SIL)

- Prepare an operating manual and provide pre-commissioning, commissioning, and start-up support

- Conduct field trips to client sites as required to determine existing operations for debottlenecking and brown field projects

Our process engineers are thorough and strategic, always improving the development of standard equipment, in-house tools, and ongoing processes.

Mechanical Engineering

Wellsmart Energy mechanical engineers aim to provide a highly efficient and reliable design for all projects. The department includes lead engineers highly experienced in stationary and rotating equipment.

Our expertise in stationary equipment design is a prerequisite for our in-house manufacturing of pressure vessels, process towers, oil treaters, fired heaters, and heat exchangers. Our engineers and designers work closely with shop fabricators to facilitate continuous improvement in the design and manufacture of process pressure equipment.

The mechanical engineering team prepares the required data sheets, calculations, finite element analysis, fabrication drawings, and material takeoffs necessary to deliver our manufactured pressure vessel.

Thanks to the team’s technical ability and practical experience in operating facilities, we can accurately select, install, and commission a wide variety of equipment. We are continuously developing standards for equipment subcomponent design to improve the overall design process and the coordination of projects between the various departments and groups.

Our Partners are OEM of reciprocating compressors. We have extensive experience in packaging reciprocating compressors driven by either natural gas engine or electric motor. Our rotating equipment specialists are also experienced in the selection, ancillary engineering, and package design of mechanical refrigeration systems using JX compressors and cryogenic turbo expansion using JX expanders.

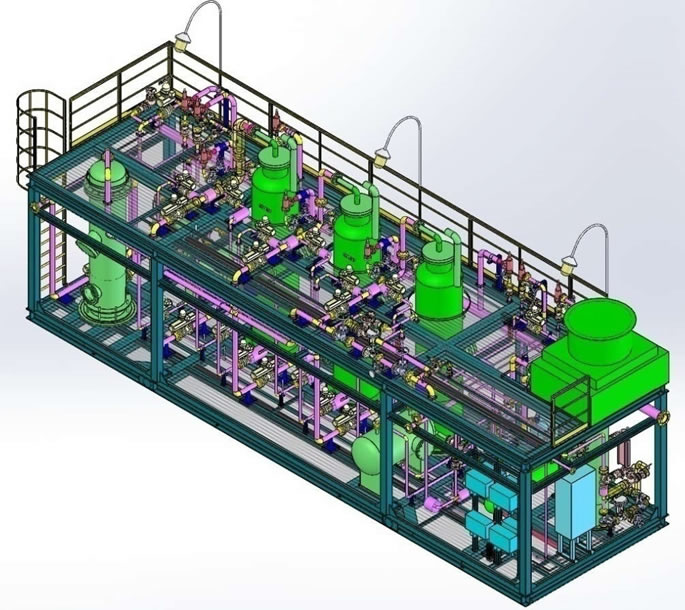

Piping Engineering

We offer detailed specification and design of the physical piping and equipment layout within process plants. Our engineers focus on efficient piping design for the proper transport of fluid. We primarily utilizes AutoCAD and AutoPLANT applications for its 3-D modelling and Isogen for piping isometric drawings generation. Other computer-aided design (CAD) applications we maintain include Plant Design Management System (PDMS), Tekla Structures, and MicroStation.

Structural Engineering

Structural engineers and designers provide safe and economical structural designs for:

- Equipment skid bases

- Pipe racks

- Cable racks

- Elevated platforms

- Compressors layout

- Facility and machinery Layout.

We typically design structures for fabrication in our Partner’s Facilities in Chengdu; and we can also design structures based on European steel shapes for overseas shop/site fabrication and erection.

Structural fabrication drawings are created by designers using either AutoCAD (for simple structures) or Tekla Structures (for complex structures with a large piece count and where a 3-D model is required). Models can be exported for use with AutoPLANT and AutoCAD as part of our plant design models.

Electrical Engineering

Our designs include power systems, gas power generation and distribution, and task lighting, as well as grounding, cable, and tray systems. The electrical engineering department focuses on design and fabrication of motor control centers and control buildings, including control panel design for programmable logic controllers and distributed control systems, with thorough development of process control systems. The group is flexible in its approach and constructs many types of modules and process plants.

We have process systems for the completion of electrical installation to various international standards (including standards of that of China, America and Nigeria) for projects, using onshore and offshore construction techniques and equipment. We work with a dedicated group of licensed electricians who maintain our high level of workmanship.

All our systems are tested before every commissioning.

Instrumentation and Automation

The instrumentation and automation department designs, programs, installs, and commissions control engineering systems.

We have the experience to execute projects that require facility-wide process control systems, emergency shutdown systems, fire and gas systems, and safety instrumented systems. Wellsmart energy has used and configured distributed control systems, programmable logic controllers, and supervisory control and data acquisition packages from numerous manufacturers, including Allen-Bradley equipment by Rockwell Automation, Siemens, Emerson, and Yokogawa, among others. We develop complete drawing/document packages that meet instrumentation and controls requirements for our projects and ensures that these systems and processes operate effectively, efficiently, and safely.